Internal Heating Tube Bitumen Tank with Heat Insulation Layers

Package Size 5800.00cm * 2200.00cm * 2150.00cm Package Gross Weight 12000.000kg Internal heating tube bitumen tank with

Description

Basic Info.

| Model NO. | BARUI-PST |

| Customized | Customized |

| Certification | ISO9001, QS, GS, TUV, GB |

| Tank Marerial | Metal Tank |

| Storage Objects | Liquid |

| Tank Anti-Corrosion | Optional |

| Tank Heat-Insulation | Optional |

| Tank Foundation Design | Optional |

| Tank Farm Design | Optional |

| Overseas Service | Included |

| Turnkey Contract | Optional |

| Quality Inspection | Magnetic Particle Test, Kerosene Penetration Test |

| Fire Fighting Engineering | Self-Build by The Owner |

| Common Storage Medium | Gasoline, Gas Oil, Fuel Oil, Bitumen |

| Internal Floating Roof | Optional |

| on-Site Installation Service | Optional |

| Operation Pressure | Common Pressure |

| Tank Installation Type | Weld Type |

| Tank Roof | Cone Roof |

| Tank Materials | Carbon Steel or Stainless Steel |

| Transport Package | Standard Container Package |

| Specification | 100 to 100, 000 CBM |

| Trademark | BARUIE |

| Origin | Henan China |

| HS Code | 7326901900 |

| Production Capacity | 14000 Ton Per Year |

Packaging & Delivery

Package Size 5800.00cm * 2200.00cm * 2150.00cm Package Gross Weight 12000.000kgProduct Description

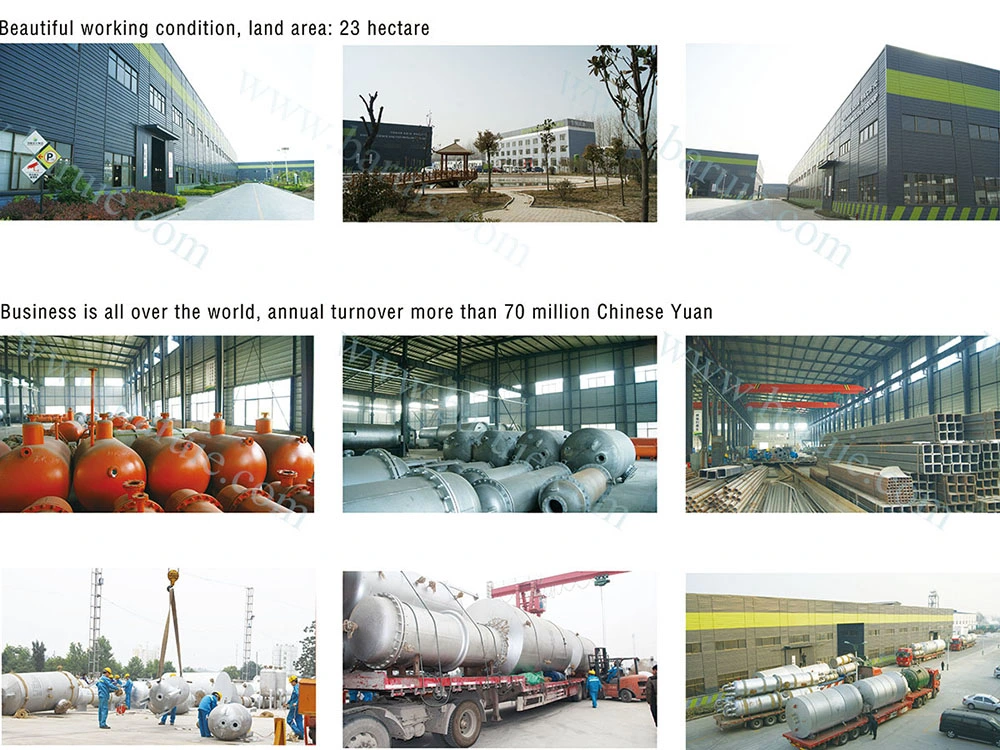

Internal heating tube bitumen tank with heat insulation layersHenan Barui company is a comprehensive group company in petroleum industry engineering, biomass engineering and environmental protection engineering. We supply complete services of oil depot construction all over the world. We ever built many oil depots for oil stations or petroleum refineries, the capacity of oil depot is from 10,000 cube meters to 500,000 cube meters. Our company also accepts subcontracted projects, like oil depot design, tank materials and accessories supply, tank installation and construction, anti-corrosion engineering construction, heat insulation engineering construction, pipeline engineering construction and so on.Common models of oil tanks for oil depot are as following sheet:

| Item | Unit | Specification of common tanks | |||||||

| Nominal Volume | m3 | 100 | 500 | 1000 | 2000 | 3000 | 5000 | 10000 | ...... |

| Actual Volume | m3 | 110 | 554 | 1100 | 2176 | 3443 | 5595 | 10907 | ...... |

| Internal Diameter | mm | 5200 | 9000 | 11500 | 15800 | 18900 | 23700 | 31200 | ...... |

Technical Stadnard:

- The manufacture, acceptance test and acceptance of this tank depends on GBJ128-90, "Code for construction and acceptance of stand cylindrical steel welded oil storage tank".

- This tank can be installed after confirming that foundation inspection is qualified.

- The technical parameter of steel plates meets the regulations of GB3274, "Carbon Structure and Low Alloy Structure Hot Rolled Thick Steel Plate and Strips ".

- Opening Holes shall keep away from the welding lines on the tank wall, the distance between the edge of joint pipes or reinforcing ring and welding lines of tank wall steel plates shall be more than 100 mm.

- After installation of the tank, the external surface shall be painted with twice primer paint and twice finish paint.

- The position of opening holes, ladders and platform is according to this drawing.

| Step 1: Foundation construction of Oil Tanks |

With the geologic examination data, make the drawings and construction scheme.

| Step 2: Pre-fabrication of oil tank materials |

| Step 3: Installation of oil tanks |

| Inspection and acceptance of oil tanks |

| Delivery site |

Our Contact

Send now